Report overview

This report is the first "Social Responsibility Report" released by Jiangsu Nanfang Communication Technology Co., Ltd. This report refers to the GRI (Global Reporting Initiative) "Sustainability Reporting Guidelines" (G3 version), and the Chinese Academy of Social Sciences "Chinese Corporate Social Responsibility Report Compilation Guidelines", combined with Nanfang Communications’ unique understanding of social responsibility and Nanfang Communications’ Prepared by specific practice.

Report scope

Unless otherwise specified, this report mainly describes the work of Jiangsu Nanfang Communication Technology Co., Ltd. in terms of company operations, internal control management, development planning, supply chain, and talent construction from January 1, 2018 to December 31, 2018. The content of the report covers the company's business in optical cable manufacturing.

Jiangsu Nanfang Communication Technology Co., Ltd.

No. 1, Cencun Road, Luoyang Town, Wujin District, Changzhou City, Jiangsu Province, China

Postal Code: 213104

Phone: +0086 519-88798288

Fax: +0086 519-88792646

Email: chinanftx@126.com

CONTENTS

Report Overview...................................... ................................................. .................1

Report Scope...................................... ................................................. ................ 2

One, Company profile............................................. ................................................. ...........3

Twe, Operating status............................................ ................................................. ...........5

Third, The organization chart ... ................................................. .........5

Four, Technological innovation............................................ ................................................. ............5

1. Research projects.............................................. ................................................. ............5

2. R&D team establishment............................................ ................................................. .....9

3. Intellectual Property Work............................................. ................................................. .....10

Five, Credit construction............................................ ................................................. ............10

Sixth, Environmental protection and conservation.................................. ................................................. ............10

1. Environmental Management............................................ ................................................. ............10

2. Resource conservation and comprehensive utilization............................................ ............................ 10

Seven, Safe production.............................. ................................................. ............11

1. Safety production management............................................ ................................................. ...11

2. Investment in safety production............................................ ................................................. ...11

3. Safety production education and training............................................ .............................................11

Eight, Employees............................................ ................................................. .................. 12

1. Labor contract and salary............................ ................................................. ...12

2. Social Security...................................................... ................................................. ............12

3. Employee benefits.............................................. ................................................. ............12

4. Occupational health and safety ... ................................................. .....12

5.Democratic management.............................................. ................................................. ...........13

6. Staff training and development............................................ ................................................. ..13

Nine, Social Responsibility............................. .................................................. ............13

1. Love and assistance.................................... .................................................. ............13

2. Employment of college students............................................ ................................................. ....... 14

Company profile

Jiangsu Nanfang Communications Technology Co., Ltd. is a subsidiary of Hong Kong listed company "Nanfang Communications Holdings Limited". The company is located in Luoyang Town, Wujin District, Changzhou City, Jiangsu Province. It covers an area of about 26,972.43 square meters. The main business is communication optical fiber and cable products. It mainly serves operators such as China Mobile, China Telecom, China Unicom, and Radio and Television, and is an important supplier. The company has won the titles of high-tech enterprise, provincial technology center, and well-known trademarks in China.

As one of the earliest enterprises that obtained the quality certification of the former Ministry of Posts and Telecommunications and the approval of the communication equipment to enter the network in 1996, Nanfang Communications is the company’s entrepreneurial spirit. "Nanfang Communications, careful selection of materials, precision manufacturing, sincere "Service" is the company's business philosophy, and "quality first, quality first, reputation first, customer satisfaction" is the company's service philosophy.

The company pays more attention to the introduction and training of talents, actively excavates and cultivates talents with innovative spirit, introduces the best allocation, cultivates reliable talents, and promotes the vigorous development of the enterprise. Responsible corporate leadership is a prerequisite for the company to be recognized by the society and achieve lasting success. Jiangsu Nanfang Communication Technology Co., Ltd. is committed to becoming a responsible and outstanding corporate citizen. The company also strives to promote the development of local society through corporate citizenship activities, and promote the rapid development of surrounding enterprises and local economic industries.

While striving to achieve the optimal allocation of resources, the company actively promotes technological progress and comprehensive quality information management. Nanfang Communications took the lead in passing the ISO9001 quality management system, ISO14001 environmental management system, and OHSAS18001 occupational safety and health management system certification in 1999. It was rated as "Private Technology Enterprise in Jiangsu Province" in 2002, and as a "High-tech Enterprise" by Jiangsu Science and Technology Department in 2007. In 2008, the company passed ISO14000 and 18000 certification. In 2009, it obtained the AAA certificate of National Standardization Good Behavior Province. In 2010, it was rated as a national "high-tech enterprise". In 2011, the company was recognized as one of the provincially recognized enterprise technology centers.

Nanfang Communications has established long-term and good partnerships with operators such as China Telecom, China Mobile, and China Unicom, as well as users of China Radio and Television, highways, railways, electric power, smart buildings, and oil fields, and established 21 regional offices. The localization and real-time of product sales, technical support and after-sales service have been realized. And the company's products have been used in China Mobile, China Unicom, China Telecom, China Railcom and other well-known companies. Driven by innovation and led by technology, Nanfang Communications has played an exemplary and radiating role in the development of the industry by virtue of its excellent quality and technological advantages, and enjoys a high reputation in the industry.

At present, the company has advanced production equipment and testing equipment, strong technical force, annual production of various types of optical cable 5 million core kilometers, more than 5,000 tons of enameled wire, the product quality is fully in line with the communications industry standards. In the past few years, the products have been sold to more than 200 telecommunications, China Unicom, radio and television, railways and electric power in Tianjin, Chongqing, Jiangsu, Anhui, Jiangxi, Hunan, Hubei, Shaanxi, Shanxi, Henan, Guangxi, Liaoning, Jilin, Gansu and other provinces and cities. The mobile company has won the trust and praise of the majority of users, and has made great contributions to the development of the country's communications industry.

Jiangsu Nanfang Communication Technology Co., Ltd. has many years of successful experience and experience in cooperating with national excellent communication enterprises, and has accumulated strong scientific and technological strength and comprehensive advantages. Through continuous multi-faceted and in-depth cooperation with domestic and foreign partners, it provides strong guarantee and support for the construction and development of communication networks. In order to expand the scale of production, Nanfang Communication and Jiangsu Hengtong Optoelectronics Co., Ltd. cooperated to establish Southern Optical Fiber in June 2013, mainly engaged in the production of optical fibers, and solved the problem of tight optical fiber supply. In the fourth quarter of 2015, a second production base was established in Jintan District, Changzhou City. Jintan Factory began trial production of optical cables to expand the capacity of optical cables. And the company successfully listed in Hong Kong on December 12, 2018, leading the company to a new milestone.

Nanfang Communications will continue to accelerate the pace of internationalization through technology and new product research and development, and strive to make greater contributions to the society's communication and transmission technology applications and solutions.

Operating conditions

In 2018, the company actively responded to the pressure of a new round of competition and concentration in the domestic optical cable industry, and worked closely around the deployment of the annual work plan. It has achieved gratifying results and achieved important breakthroughs and growth in various business modules. At the end of the year, the number of employees reached 200, and the scale of operations continued to maintain good growth. The company's industry position was further improved and consolidated. In particular, the company's mainstream technology products have gained high market recognition. In 2018, the company achieved sales revenue of 887 million yuan, profits and taxes of 156 million yuan, of which 54 million yuan was paid in taxes

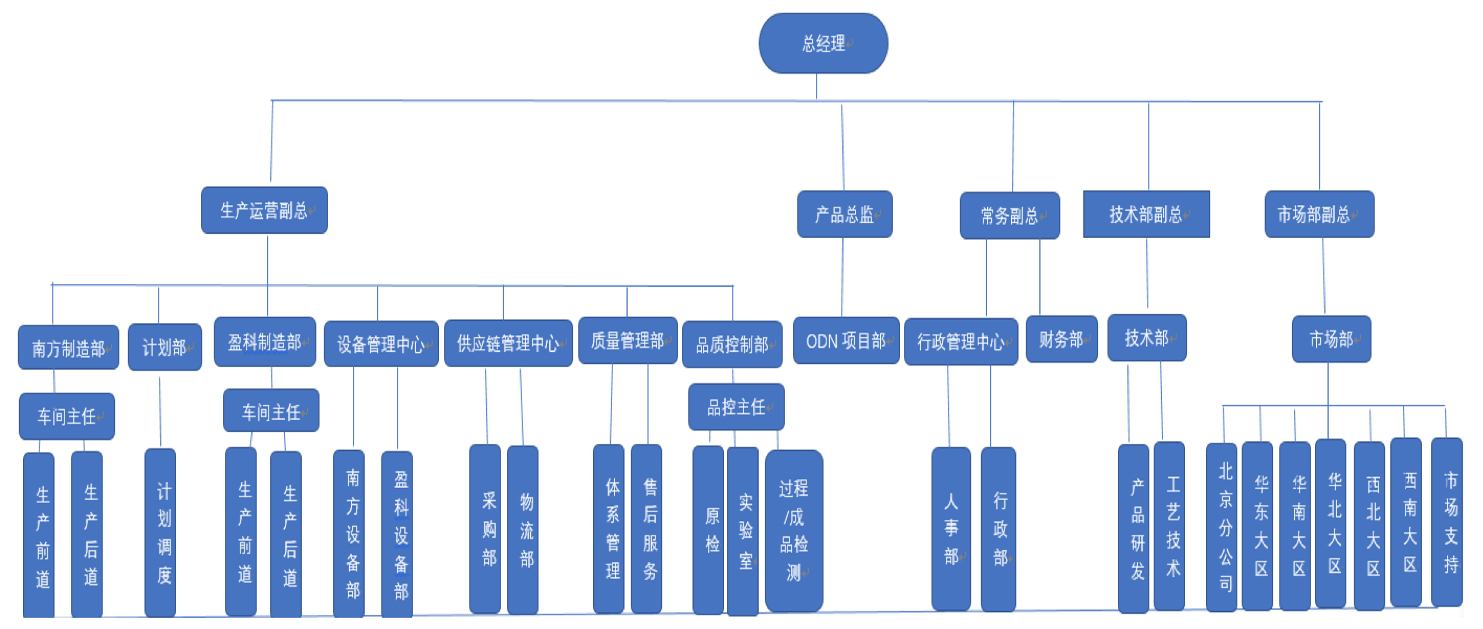

Organization Chart

Technological innovation

1. Research projects

Jiangsu Nanfang Communication Technology Co., Ltd. relies on seven scientific research platforms:

"Postdoctoral Workstation"

"Graduate Workstation"

"Jiangsu Enterprise Technology Center"

"Changzhou Enterprise Technology Center"

"Changzhou Engineering Technology Center"

"Comprehensive Laboratory of Optical Fiber and Cable Products and Materials"

"New Product Incubation Center"

The company relies on seven platforms to develop new products, and has four sub-technical centers within the company:

"Optical Fiber and Cable Product Technology Research Center"

"ODN Product Technology Research Center"

"New Materials Research Center"

"Equipment and Intelligent Research Center"

Each sub-technical center has a dedicated director, standing committee and members, etc., under the overall leadership of the director of the enterprise technology center. Under the support of the laboratory, the sub-technical centers carry out the development of new products, and rely on the new product incubation center for large-scale production and promotion of the new products that have been developed.

Focusing on the development strategy of transforming from a production enterprise to a research and development enterprise, Nanfang Communications is committed to the development of new products and technological innovation, and constantly develops new products with independent intellectual property rights in accordance with industry trends and user needs to enhance Nanfang Communications’ comprehensive Competitiveness. At the same time, a provincial new product appraisal meeting will be held to conduct expert appraisal of the company's new products with core market competitiveness to ensure the advanced technology and performance indicators of the new products.

New product achievement identification certificate

Flat single-fiber ribbon flexible optical cable: This product was implemented in 2015 and completed in 2 years. Mainly developed a flat single-fiber ribbon soft optical cable for indoor laying, completed the supporting work of related processes, molds, equipment, and materials, and successfully developed a flat single-fiber ribbon soft optical cable.

Low-loss optical fiber: The product was implemented in 2015 and completed in 2 years. This project is to develop low-loss optical fiber drawing technology and related equipment, and realize the 1550 window loss of G652D optical fiber to reach the level of 0.180-0.185dB/Km.

Loose tube multi-fiber ribbon optical cable for indoor use: This product was implemented in 2015 and took 2 years to complete. Mainly developed a loose tube multi-fiber ribbon optical cable for indoor laying, completed the related work of related processes, molds, equipment, and materials, and successfully developed an indoor loose tube multi-fiber ribbon optical cable.

Wireless remote photoelectric hybrid cable: This product was implemented in 2015 and took 2 years to complete. The research period is to develop a photoelectric hybrid cable for wireless remote control. The project involves the structural design, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial of the product, and the power supply line of the wireless base station is mixed In the optical fiber cable for communication transmission, the photoelectric co-cable access of the wireless base station is realized.

High-density optical fiber ribbon cable: The product was implemented in 2016 and completed in one and a half years. Mainly developed a high-density optical fiber ribbon cable for access network, completed the related work of related processes, molds, equipment, and materials, and successfully developed a high-density optical fiber ribbon optical cable.

Figure 8 self-supporting micro-optical cable: This product was implemented in 2015 and completed in 2 years. This new product research project is to research and develop a figure-eight self-supporting miniature optical cable. The project involves the structural design of the product, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial, to realize figure-eight self-supporting The miniaturization of optical cables provides a convenient solution for the application of optical cables in access networks.

Double-layer protective mouse bite-resistant fiber optic cable: This product was implemented in 2015 and took 3 years to complete. This research period is to develop a double-protected mouse bite resistant optical cable. The project involves the structural design, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial of the rodent resistant optical cable product, which is serious for some rodents. Regional communication optical cables provide new solutions. Obtained a utility model patent for "New Type Anti-rat Optical Cable".

Protective mouse bite-resistant butterfly optical cable: This product was implemented in 2015 and took 3 years to complete. This research period is to develop a protective mouse bite-resistant butterfly optical cable. The project involves the structural design of the optical cable product, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial, and it is introduced into some areas with severe rodent damage. Provide a low-cost butterfly optical cable solution with a certain degree of resistance to mouse bites.

Flat non-metallic anti-bird-pecking optical cable: This product was implemented in 2015 and took 3 years to complete. This research period is to develop a flat non-metallic anti-bird-pecking optical cable. The project involves the structural design, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial of the optical cable product, which is a communication for some areas with severe bird damage. The optical cable provides a low-cost optical cable solution with a certain degree of bird-pecking ability.

Fire-resistant optical cable: The product was implemented in 2015 and completed in 3 years. This research period is to develop a fire-resistant optical cable. This project involves the structural design, process design, tooling equipment design and improvement of fire-resistant optical cable products, product trial production, testing and trial, and provides communication optical cables for some important places and requiring fire-resistant environments. A more reliable option.

Stranded micro-bundle tube optical cable: This product was implemented in 2015 and took 3 years to complete. The main research and development of a stranded micro-bundle tube fiber optic cable, the completion of related processes, molds, equipment, and materials, successfully developed a stranded micro-bundle tube fiber optic cable, providing a new solution for the miniaturization of the fiber optic cable.

Stranded micro-bundle tube optical cable: This product was implemented in 2017 and completed in 2 years. Mainly developed a stranded micro-tube optical cable, completed the related process, mold, equipment, and materials, and successfully developed a stranded micro-tube optical cable, providing a new solution for optical cable miniaturization.

Ultra-low loss and large effective area single-mode fiber: The product was implemented in 2016 and completed in 2 years. The main research and development of an ultra-low loss large effective area single-mode fiber, completed the related preform process, wire drawing process, special equipment and testing equipment supporting work, successfully developed a ULL fiber 1550 window loss less than 0.175dB/km Ultra-low loss single-mode fiber with large effective area.

Micro-tube Figure 8 self-supporting optical fiber cable: This product was implemented in 2017 and completed in 2 years. Mainly researched and developed a kind of micro-tube and figure-eight self-supporting optical cable. The project involves the structure design, process design, supporting design and improvement of tooling equipment, product trial-manufacture, test and trial of micro-tube and figure-eight optical cable products. A kind of 8-shaped self-supporting optical cable with micro-bundle tube has been developed to provide a new solution for the miniaturization of optical cable.

Full dry optical cable: This product was implemented in 2017 and completed in 2 years. The main research and development of a dry type optical cable, the completion of related work, molds, equipment, materials, and the successful development of two types of stranded and central tube structure of the dry type optical cable.

All-dielectric figure-eight self-supporting optical fiber cable: This product was implemented in 2016 and completed in 2 years. Mainly developed a kind of all-dielectric figure-eight self-supporting optical cable, completed the related process, mold, equipment, and material supporting work, and successfully developed a kind of all-dielectric figure-eight self-supporting optical cable, which is suitable for outdoor areas and mine areas. Overhead optical cable lines provide new solutions.

Central tube type yarn fiber bundle optical cable: This product was implemented in 2017 and completed in 2 years. The main research and development of a central tube type yarn bundle fiber optic cable, the completion of related processes, molds, equipment, materials, and successfully developed a central tube type yarn bundle fiber optic cable, which is a high-density large core number central tube Optical fiber cables provide new solutions.

New products with invention patent certificates (invention patents have passed the normalization certification audit)

New type of optical fiber ribbon and optical fiber ribbon optical cable: The product was implemented in 2008 and completed in 2.5 years. The main innovative technology adopts a new type of optical fiber and ribbon technology and materials, and has completed the improvement and application of related processes and equipment, and successfully developed a new type of optical fiber ribbon and optical fiber ribbon optical cable.

New type of discrete optical fiber skeleton trough optical cable: This product was implemented in 2010 and took 2 years to complete. The main innovative technology is the improvement of the traditional skeleton trough type and the improvement of the filling material and the improved application of related processes and equipment, and the successful development of a new type of discrete fiber skeleton trough optical cable.

Rubber sheathed photoelectric composite cable: This product was implemented in 2011 and took 1.5 years to complete. The main innovative technology is to use a high temperature resistant rubber material as the sheath of the photoelectric composite cable, complete the improved application of related processes and equipment, and successfully develop a rubber sheathed photoelectric composite cable.

New type of optical fiber drop cable: This product was implemented in 2011 and completed in 2.5 years. The main innovative technology is the design and development of a new structure of the optical fiber drop cable, completion of the related processes, equipment and materials, and the successful development of a new type of optical fiber drop cable.

New all-dielectric fiber optic cable: This product was implemented in 2013 and completed in 2 years. The main innovative technology is to adopt a new type of non-metallic reinforced conforming tape material, complete the improved application of related processes and equipment, and successfully develop a new type of all-dielectric optical cable.

New-type stranded optical cable: This product was implemented in 2014 and completed in 2 years. The main innovative technology is to adopt a kind of optical cable structure with different casing sizes and mixed layer stranding of the stranding unit, complete the improved application of related processes and equipment, and successfully develop a new type of layered optical cable.

Environmentally friendly flame-retardant optical cable: This product was implemented in 2013 and completed in 3 years. The main innovative technology is to use an environmentally friendly high flame retardant, ointment and sheath material, complete the improved application of related processes and equipment, and successfully develop an environmentally friendly flame retardant optical cable.

Underground fiber optic cable: This product was implemented in 2016 and completed in 2 years. This research period is to develop a downhole optical cable. The project involves the structural design, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial of downhole optical cable products, and provides solutions for underground detection and communication.

Asphalt waterproof coating optical cable: This product was implemented in 2017 and completed in 1.5 years. The main innovative technology is to use a polymer modified water-emulsion asphalt as the sheath of the optical cable, complete the improvement and application of related processes and equipment, and successfully develop a new type of waterproof stranded optical cable

Fire-resistant and waterproof coated optical cable: This product was implemented in 2017 and completed in one and a half years. The main innovative technology is to use a modified waste slag fire-resistant and waterproof coating as the outer layer of the optical cable, and complete the improvement and application of related processes and equipment

New product planning under research

200μm small diameter G.652D optical fiber research and development project: This project was implemented in 2017 and is still under development. This project is to develop a G.652D fiber drawing process and related equipment with an outer diameter of 200μm. The performance index of the fiber is the same as that of ordinary G652D fiber, but the new G.652D fiber with a smaller diameter is the future miniaturization of optical cable structure. Offer support.

The research and development project of separable photoelectric integrated optical cable for 5G small and micro base stations: The project was implemented in 2018 and is planned to be completed in 2 years. This research period is to develop a separable photoelectric integrated optical cable for 5G small and micro base stations. The project involves the structural design, process design, supporting design and improvement of tooling equipment, product trial production, test and trial of the optical cable product, which is for the future 5G construction Medium, small and micro base stations provide a solution for separable photoelectric integrated optical cables. At present, the product structure design and process route design have been completed.

R&D project for indoor deployment of optical cables in industrial environments: The project will be implemented in 2019 and is planned to be completed in two years. This research period is to develop an optical cable for indoor deployment in an industrial environment. The project involves the structural design, process design, supporting design and improvement of tooling equipment, product trial production, testing and trial of the optical cable, and provides solutions for indoor deployment in industrial environments. Program. The related work of product structure design has been completed.

2. R&D team establishment

The company attaches great importance to the construction of a team of technical personnel, and increases a large number of talents every year through various channels such as introduction, recruitment and training. At the same time, it also actively introduces mature talents from the society to meet the urgent needs of scientific research and development, and cultivate and cultivate a team of high-quality and innovative talents that are compatible with the company's development. At present, there are 35 R&D personnel in the company's technology center, and 7 have intermediate and senior titles.

3. Intellectual Property Work

As of 2018, the company has obtained 80 authorized technology patents, including 18 invention patents and 62 utility model patents. Currently, the company has a total of 23 accepted patents in application, including 7 invention patents and 16 utility model patents.

Five, Credit construction

The company has always taken credit management as an important part of the company’s daily management. In the modern society where the market economy is increasingly developed, we are well aware that “abiding by contracts and respecting credit” is the foundation for the survival and development of enterprises, and the credit qualifications of enterprises have An important label indispensable for enterprises in market competition. The company always adheres to the principle of honesty and welcoming customers with faith, and has won positive comments and full trust from customers.

Six, Environmental protection and conservation

1. Environmental Management

The company has passed the ISO14000 environmental management system certification, enhancing its environmental management capabilities. Establish a special environmental management organization, improve and improve the environmental management system and incorporate it into normal management, record the operating data of environmental protection facilities and establish environmental protection files. Establish and improve emergency plans for environmental pollution accidents, and regularly organize drills. Strengthen the management of production technology and equipment, make full use of various resources and energy, increase the utilization rate of raw materials and energy, and produce no or less waste. If the pollution problem can be solved through maintenance and replacement of equipment, it is necessary to stop production for maintenance and replace the equipment in time.

2. Resource conservation and comprehensive utilization

The company resolutely eliminates waste of resources. Wood resources are non-renewable resources. Use a little less. The company recycles the pallets used for transportation, which greatly reduces wood consumption. In addition, the company in 2018 has also continuously improved its production and processing techniques to reduce energy consumption while improving production efficiency.

Seven, Safe production

1. Safety production management

The company adheres to the safety production policy of "safety first, prevention first". Gradually implement modern safety management, pay attention to the safety and health of employees in operation, establish a company safety production leadership group, clearly have a safety management department, and have full-time and part-time safety management personnel. The safety production management network is sound, and safety at all levels is established. Production responsibility system, safety production management system, functional departments have clear responsibilities, and have obtained the "Safety Production Standardization Certificate" issued by Changzhou Safety Production Supervision Administration.

2. Safety production investment

The company formulates and strictly implements safety production budgets in accordance with national laws and regulations, and organizes the implementation of safety improvement projects. Every year, funds are invested to provide employees with the safety resources they need, including personal protective equipment, labor protection equipment, etc., to prevent occupational injuries, diseases, accidents, and emergency handling. In accordance with the safety requirements of "strengthening management and control, preventing theft, and separating people and vehicles", the "safety technical defense project" is implemented to protect the safety of enterprise property, protect the vital interests of employees, and maintain the normal operation and management order of the enterprise. Safety management level.

3. Safety production education and training

Employees are the most valuable asset of an enterprise, and the development of an enterprise cannot be separated from employees. Our company has always regarded safety production and employee labor protection as the top priority of all work, and effectively safeguarded the life safety and occupational health of employees. In order to further strengthen the safety of the company, create a good atmosphere of "safety management, everyone is responsible", and establish the ideological awareness of safety as the heavens, in June 2018, the company's trade union and relevant departments held the launch of the 2018 "Safety Production Month" activity The ceremony, combined with the launch of the "Safety Production Month" "Safety Knowledge Assessment and Appraisal" activity, promoted the company's safety production work to a new level. This activity adheres to the "safety hazard investigation and management" as the main line, continuously consolidates the safety foundation, in-depth implementation of hidden hazard investigation and management and safety supervision work, publicizes safety production guidelines and policies, and combines the company's "high-quality, high-price" and "five members" "Effective Plan Management" and other activities, reasonable deployment and overall promotion, make safety production management deeply rooted in the hearts of the people, further improve the safety awareness and responsibility awareness of all cadres and employees, and form a consensus of "safe production, people-oriented".

Eight, Staff

1. Labor contract and salary

The company strictly abides by and fully implements the "Labor Contract Law of the People's Republic of China" and other laws and regulations, signs written labor contracts with employees in accordance with the principles of lawfulness, fairness, equality and voluntariness, and executes, changes, cancels and terminates labor contracts in accordance with the law. The labor contract signing rate is 100%. The company formulates a fair and reasonable remuneration system and pays employees in full and on time. Follow the principle of simultaneous improvement of corporate operating efficiency and employee income, and determine the annual average wage growth rate based on the company’s annual operating goals, combined with the wage growth guidelines issued by this city, and comparing labor costs and labor market wage guidance prices in the same industry. Due to the needs of production and operation, the arrangement of overtime requires the consent of the employees, and the settlement of overtime is made.

2. Social Security

The company pays social insurance such as pension, unemployment insurance, and medical insurance for employees in accordance with the law.

3. Employee benefits

In order to enrich the employees' spare time, the company also organizes various types of activities, such as the company's annual meeting, lantern riddles guessing activities and other activities, which enlivens and enriches the staff's spare time, stimulates the enthusiasm of the staff, and strengthens everyone's cohesion.

The company advocates people-oriented, employees are the company's greatest wealth, the company earnestly understands the actual working conditions of the employees and what they think and ask, and solve problems for them. In order to better serve the employees, the company actively organized and planned a series of special events. For example: this year's "March 8 Women's Day", the company carefully prepared gifts for female employees. In the hot summer, the general manager of the company personally went to the front line to distribute heatstroke prevention and cooling products to employees. At the same time, the company commends advanced individuals, publicizes the outstanding deeds of employees, and promotes the corporate spirit embodied in employees.

4. Occupational Health and Safety

Pay attention to the physical and mental health of employees and conduct a general health survey of all employees. The company conducts a general health survey for employees and a gynecological examination for female employees once a year. Established employee health electronic files. At the same time, we actively carry out occupational health promotion and use comprehensive methods such as the release of disease prevention information and knowledge to care about employees' health and reduce disease hazards.

5. Democratic management

The company establishes a sound union organization in accordance with the law to protect the rights and interests of employees. Support trade unions to carry out various activities in accordance with the law, communicate with trade unions regularly, and actively respond to reports, suggestions and opinions submitted by trade unions and their representatives. The chairman of the trade union participates in the preparation and discussion of rules and regulations concerning the vital interests of employees, and is reviewed and determined through the employee (representative) conference and other channels. Establish a collective wage negotiation mechanism to conduct equal negotiation on related major issues, such as wage adjustment mechanism, incentive wages, overtime wages, minimum wage levels, etc.; insist on holding employee representatives before the introduction of various reform measures involving employee interests The meeting will be implemented after it is passed by voting. The company fully supports employees to participate in labor unions and encourages employees to participate in democratic management through multiple channels. Such as: Staff Representative Conference system, democratic appraisal of leading cadres, etc. The company established a labor dispute mediation committee composed of the party branch, labor union and employee representatives to establish labor dispute mediation procedures.

6. Staff training and development

Carry out all-round, multi-level and systematic education and training. The company divides the training content into four types: induction training, on-the-job training, skills training, and management training. The training forms are divided into external training and internal training. The company implements personalized employee learning and development plans. For management employees, the company invites external training companies to conduct customized management-related training. For on-site personnel, a series of activities and trainings are carried out for different positions, such as induction training, class leader training, job skills training, etc.

In addition, various workshops and teams are organized to conduct various skill competitions within the company, and outstanding employees are rewarded. Fully mobilized the enthusiasm of employees to conduct professional production and strengthen operational skills.

Nine, social responsibility

The company shoulders social responsibility and actively participates in social welfare undertakings such as poverty alleviation and employment of college students, and has achieved good social benefits.

1. Love and assistance

In 2015, Jiangsu Nanfang Communication Technology Co., Ltd. donated 300,000 yuan to the Red Cross Society of Wujin District, Changzhou City, Jiangsu Province; in January 2016, it donated 3.3 million yuan to Changzhou Guangcai Industrial Promotion Association; in March 2017, it donated to Wujin, Changzhou City District Charity Federation donated 300,000 yuan; in April 2017, it donated 400,000 yuan to Changzhou Guangcai Industrial Promotion Association; in December 2018, it donated 35,700 yuan to Changzhou Guangcai Industrial Promotion Association;

2. Employment of college students

In order to better implement the strategic decision of higher education to serve the country's economic construction, strengthen the "production, study and research" cooperation between colleges and universities, enterprises, institutions, and scientific research institutes, and strengthen scientific research cooperation, talent training, and academic exchanges between companies and colleges and universities. In 2018, a total of 10 college graduates were accepted.

STOCK CODE:1617.HK

STOCK CODE:1617.HK